The global yarn manufacturing industry plays a crucial role in the textile sector, serving as the foundational element for a diverse range of fabrics and garments. With a wide array of yarn types available, the industry caters to various needs and preferences, from cozy animal fiber yarns to durable synthetic alternatives.

Manufacturers worldwide, including those from China, India, Pakistan, Vietnam, and Bangladesh, contribute significantly to the market with their specialized products.

Quality control remains paramount in yarn production, ensuring that the threads meet stringent standards before reaching consumers. As the demand for textiles continues, understanding the intricacies of yarn types and the capabilities of leading manufacturers is essential for stakeholders in the fashion and textile industries.

Yarn production is closely tied to its derived demand through the apparel industry, itself worth an astounding $1.5 trillion. As the garment sector grows, so too does the need for yarn, benefiting the yarn industry at large.

Types Of Yarn

- Natural: Includes cotton, wool, silk, and linen.

- Synthetic: Includes polyester, nylon, and acrylic.

- Blended: A mixture of natural and synthetic fibers.

Growth Trends

- Natural yarns see heightened demand from eco-conscious consumers.

- Synthetic yarns offer cost-effectiveness and durability.

- Blended yarns provide a balance of quality and functionality.

The types of yarn vary greatly with natural, synthetic, and blended fibers making up the market. Each type has different uses and market growth; while some see rapid increases in production and demand, others may plateau.

The market also shows an increasing inclination toward more sustainable and eco-friendly yarns, aligning with a global push towards environmental awareness. Industry players focusing on these eco-products stand to gain from this shift in consumer preferences.

Looking at the current state and anticipated trajectory of the yarn manufacturing industry, one observes the influence of global trends, consumer behavior, and technological innovation. The industry prepares to meet future demand, welcoming both traditional market players and those poised to introduce sustainable practices.

What types of yarn are there?

Animal Fiber Yarns

Wool Yarn

Wool yarn, ideal for winter garments, provides warmth and retains shape well. Common for sweaters, scarves, and gloves, wool’s unique trait is its fire retardant quality. Known to offer coolness in heat, varieties include:

- Fine Wool

- Medium Wool

- Long Wool

- Double-Coated Wool

Cashmere Wool Yarn

Soft and luxurious, cashmere originates from the goats of historic Kashmir. It is less itchy than other wools and is considered a high-cost fiber, best suited for high-end socks and gloves.

Alpaca Wool Yarn

Alpaca wool, harvested from South American alpacas, is coveted for its silk-like softness and warmth, often used in sweaters. While it may lack shape retention, its water repellency and low flammability stand out.

Merino Wool Yarn

Sourced from Merino sheep, this hypoallergenic wool is extremely soft and maintains shape. Favored for winter wear, Merino Wool’s resilience includes withstanding being bent over 20,000 times without breaking.

Mohair Yarn

Mohair, derived from Angora goats, combines softness with shine. Durable and resistant, it exhibits moisture-wicking and insulative properties, making it seasonally versatile, though potentially itchy for some.

Organic Yarn

Chemical-free and eco-friendly, organic yarns are mainly harvested from Merino sheep. Focused on animal welfare, these yarns are predominantly used in environmentally conscious knitting projects.

Silk Yarn

Praised for its strength and sheen, silk stands as the most premium of fibers, characterized by its slippery texture. Known for its luxurious feel, silk’s cost reflects its prized status in the textile world.

Plant Fiber Yarns

Cotton Yarn

Derived from the cotton plant, cotton yarn is strong, breathable, and dominates in warmer climates. Used for summer clothing due to its high absorbency, the primary drawback is its tendency to lose shape.

Hemp Yarn

Emerging as a knitting fiber, hemp is celebrated for its delicate feel and stitch definition. It produces more fiber than cotton and is primarily used in outerwear and robust socks.

For more details about Hemp Yarn Manufacturers, Click Here.

Bamboo Yarn

A natural choice admired for its antibacterial properties and soft touch, bamboo yarn provides excellent breathability. It’s an excellent choice for garments due to its comfort and silk-like softness.

Synthetic Fiber Yarns

Acrylic Yarn

A budget-friendly, man-made option, acrylic yarns are easy to clean, fast-drying and maintain color well. Ideal for vibrant and washable crafts, acrylic is popular in the creation of braids and novelties.

Novelty Yarns

Novelty yarns come in an array of textures and colors, often based on synthetic blends to enhance the tactile sensation. Categories include:

- Chenille: Velvety softness that can be difficult to knit due to its texture.

- Boucle: Notably bumpy and looped, adding texture to projects.

- Faux Fur: Extra fluffy, woven on a strong nylon base.

- Thick-Thin: A mix of thick and thin sections, creating a dynamic visual effect.

- Railroad Ribbon: Characterized by “tracks” between strands, resembling a network of rails.

Polyester Yarn

Polyester yarn blends with cotton and wool to offer durability. Ribbon yarn, a type of polyester, stands out for crafting items like headbands, bags, and belts. Knotting can be challenging due to its tendency to twist and spin.

Self-Stripping Yarn

Known for automated color changes that create unique patterns during knitting. These yarns make knitting intriguing, especially for beginners. Despite higher costs, the visual effect achieved is often worth the investment.

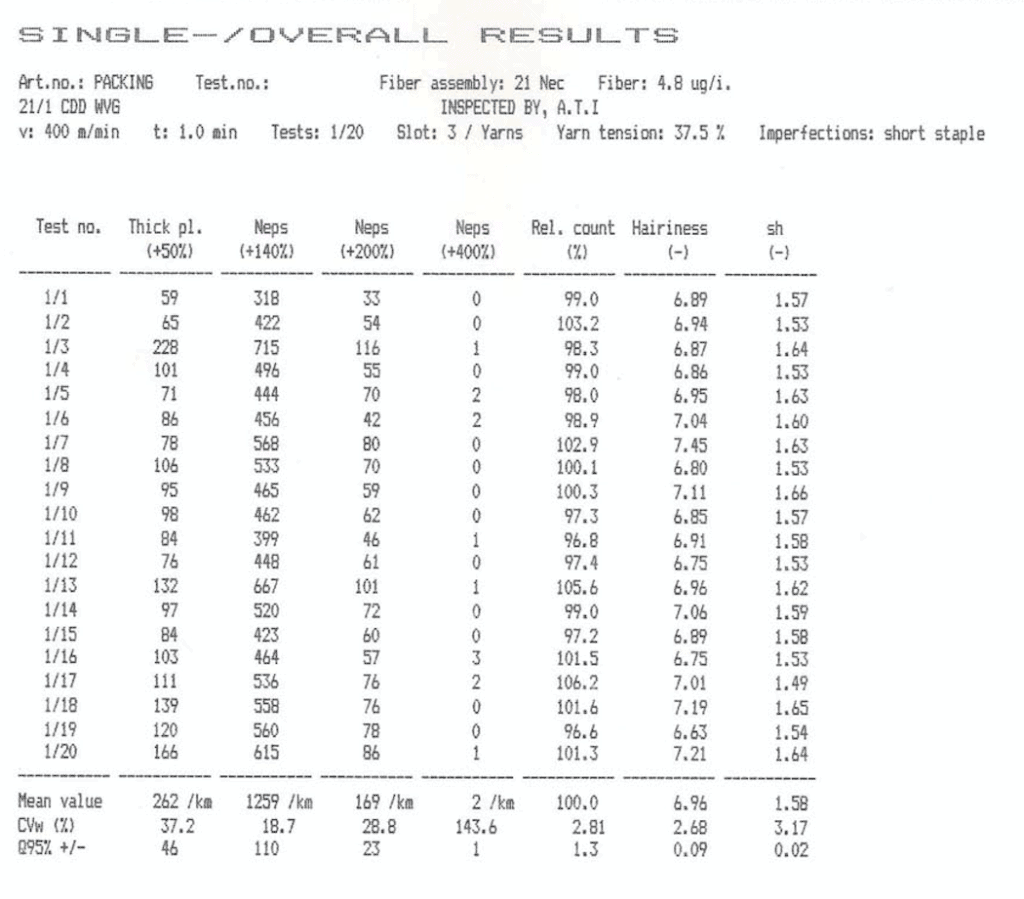

Yarn Quality Control Method

Ensuring the quality of yarn involves considering various factors that influence its characteristics. Fiber Selection is a primary step; utilizing superior fibers leads to higher yarn quality.

Atmospheric Conditions play a role too:

- Moisture: Fibers are hygroscopic and absorb moisture from the air, hence controlling the Relative Humidity (RH) and temperature is vital to maintain fiber integrity.

- Recommended RH levels are essential to prevent excessive absorption, which can weaken fibers and degrade yarn quality.

Fiber Length considerations include:

- Short Fiber Content: An increased proportion can lead to heightened irregularity and processing issues.

- Staple Length: Longer fibers contribute to enhanced strength and uniformity in the final yarn. Shorter lengths result in a weaker structure.

The Uniformity Ratio is also crucial to yarn’s quality:

- A lower uniformity ratio indicates a consistent yarn with less variability, deemed higher quality.

- Conversely, a higher ratio suggests increased irregularity, impacting its performance and application.

Quality control methods also make extensive use of testing equipment to ensure these attributes are within optimal ranges:

- Machines like the Uster Tester assess yarn for strength, elongation, and evenness.

- Results from these tests give insights into the yarn’s uniformity and overall quality.

Uniformity in production is mirrored in the test outcomes, where a lower discrepancy between measurements correlates with superior yarn quality.

Lists Of Yarn Manufacturers in Different Countries

List Of Yarn Manufacturers in China

- QINGDAO FAB MILL CO., LTD.

- Certifications: ISO 9001

- Output Value: Up to $2.5 million

- MOQ: 500 to 1,000 pieces

- FOB Price: $1.2-$2.5 / piece

- Services: OEM, ODM; Own brand available

- Export Markets: Americas, Europe, Asia, Africa, Oceania, Middle East

- SHENZHEN CITY XINYE-TEX INDUSTRIAL CO., LTD.

- Established: 1985

- Area: 410,000 square meters

- Output Value: Up to $2.5 million

- MOQ: 500 kg to 1,000 kg

- FOB Price: $1.50-$2.80 / kg

- Brands: Sunrisetex, Xinye

- Export Markets: Americas, Southeast Asia, Oceania, Eastern Asia, Western Europe

- QINGDAO PROWAY CO., LTD

- Established: 2005

- Output Value: Up to $10 million

- Export Revenue: Up to $2.48 million

- MOQ: 2,000 LBS (negotiable)

- FOB Price: $8.8-$10.5 / LBS

- Clients: J. C. Penney, M&S, H&M, Zara

- Export Markets: Southeast Asia, Middle East

- JIANGXI LONGTAI NEW MATERIAL CO., LTD.

- Established: June 1st, 1999

- Certifications: ISO 9001

- Area: 15,000 square meters

- MOQ: 2,000 pieces (negotiable)

- FOB Price: $2.00-$3.50

- Payment Terms: LC, T/T

- Export Markets: Americas, Europe, Southeast and East Asia, Africa, Oceania, Middle East

- ZHEJIANG HAILUN ROPE AND NET CO., LTD.

- Established: 2008

- Certifications: ISO 9001

- Output Value: Up to $100 million

- MOQ: 1 roll

- FOB Price: $1.4-1.7 / roll

- Services: ODM, OEM

- Export Markets: Americas, Europe, Asia, Australia, Domestic

Article on Yarn Manufacturers in China

List Of Yarn Manufacturers in India

- ALOK INDUSTIRES LTD

- Established: 1986

- Certifications: ISO 9001:2015, ISO 14001:2015, OHSAS 18001:2017, ISO/TS 16949:2009, ISO/IEC 17025:2005, OEKO TEX 100, GOTS, FLO

- Products: Cotton yarn

- Awards: Multiple from 2006-2014

- SUTLEJ TEXTILES & INDUSTRIES LTD (STIL)

- Established: 1934

- Awards: Gold trophy for highest exports in cotton yarn

- Income: $370.49 million USD

- Key Markets: Turkey, Bangladesh, USA, Poland, Egypt, Italy, Portugal, Colombia, Africa, South Africa, Morocco

- ARVIND LIMITED

- Established: 1931

- Employees: 42,000

- Income: $935.72 million USD

- Products: Yarn products

- Brands: Tommy Hilfiger, US Polo, CK, GAP, Nautica, Sephora

- VARDHMAN TEXTILES

- Established: 1962

- Capacity: 1.1 million spindles; 580 MT of yarn/day

- Products: Specialized dyed, cotton, polyester and blended yarns

- Income: $949.03 million USD (FY19); $710.56 million USD (9MFY20)

- Exports: EU, US, Far East

- SEL GROUP

- Products: Yarn and fabric

- Facilities: Spinning, knitting, processing

List Of Yarn Manufacturers in Pakistan

INTERLOOP LIMITED

- Established: 1992

- Stock Exchange: Pakistan Stock Exchange

- Employees: 23,000

- Worth: Over $280 million

- Facilities: Spinning, Yarn Dyeing, Knitting, Finishing

- Awards: ‘Best in Quality’ Award from C&A for 2012-2013 and 2016-17

- Clients: Nike, Adidas, Puma, Reebok, Calvin Klein

Indus Dyeing & Manufacturing Co. Limited

- Founded: 1957

- Part of: Indus Group of Pakistan

- Revenue (2019): Over $70 million

- Products: Ring-spun yarns (melange, pima cotton, synthetic, slub-effect, folded yarns)

- Production (2019): 342,000 tons of yarn

- Growth: Expanding in revenue and machinery, frequent upgrades for high-quality production

Nishat Mills Limited

- Established: 1951

- Stock Exchange: Listed on the Pakistan Stock Exchange

- Exports: Over $344.744 million annually

- Capacity: 227,640 spindles, 200 tons/day of cotton & blended yarns

- Products: Ring-spun yarn for knitting and weaving, uses various high-quality cotton including American and Egyptian

- Focus: Strong emphasis on research, product development, and in-house yarn testing

Sapphire Textile Mills Limited

- Founded: 1969

- Market Share: More than 10%

- Production (2019): 98,423,297 20/s lbs of yarn

- Capacity: 139,433 spindles with advanced technology

- Exports: Asia, Europe, North America

- Certifications: ISO, SA, GmbH, GOTS, Oeko-Tex, Sedex, BCI

- Diversification: Produces fabric, home textiles, and other textile products

Reliance Cotton Spinning Mills Limited

- Established: 1991

- Parent Company: Sapphire Fibres Limited

- Exports: Over 84% of production

- Annual Production: Exceeds 8,300 tons

- Products: Premium yarns (plied, slubs, mélanges, blends, special fibers)

- Growth: Significant market presence

- Certifications: OCIA International, Control Union Certifications, ISO

Fazal Cloth Mills Limited

- Founded: 1966

- Capacity: 198,804 Spindles, 6,108 tons of yarn/month

- Turnover: Exceeds $220 million annually, primarily from exports

- Products: Various yarns (cotton, rayon, polyester cotton, modal cotton, bamboo cotton)

- Workforce: Employs over 5,300 people

- Certifications: BCI, LYCRA, USA Cotton, SUPIMA, ISO, Amfori

Each of these companies is a significant player in Pakistan’s textile industry, showcasing robust growth, extensive product lines, and a commitment to quality and innovation.

List Of Yarn Manufacturers in Vietnam

TRINH TRUNG LA CO., LTD

- Specialty: Producing polyester yarn

- Exports: China, India, USA

- Production Capacity: 160 tons/day with modern technology

- Factory Size: 20,000 square meters

- Product Range: Yarn sizes from 0.9D to 25D

- Services: Custom yarn samples upon request

VIET LONG IMPORT EXPORT TRADE AND PRODUCTION CO., LTD

- Founded: 2008

- Experience: Over 10 years

- Products: PP, cotton, polyester, nylon yarns

- Quality: High durability, diverse models

- Pricing: Competitive with incentives

- Location: 10,000 square meters facility in Vietnam

- Workforce: Enthusiastic, experienced, open to suggestions

- Market: Currently limited to Vietnam, plans to expand internationally

TAI NGUYEN CO., JSC

- Focus: Manufacturing and exporting fabrics and yarns

- Export Markets: Europe, USA, Korea, Japan, Singapore, China, India

- Reputation: Top exporter in Vietnam

- Commitment: Quality, reasonable pricing, professional service

- Products: Variety of yarns including TC, CVC, CD, CM, OE, PE, polyester slub, cotton carded slub

BAO LAN TEX CO., LTD

- Established: April 2011

- Production Capacity: Over 150 tons/day

- Specialty: Cellulose yarn, fancy yarn, recycled yarn, sustainable yarn, eco yarn, organic yarn, special yarn, UV Yarntech yarn

- Approach: Customer-centric, environmentally and socially beneficial

- Quality and Pricing: Competitive, accessible to small businesses

DTY YARN – DOTIHUTEX CO., LTD

- Founded: 1993

- Specialty: Spinning polyester DTY yarns

- Product Range: Drawn textured yarn, PE, cotton yarn, polyester spun yarn, CD yarn, TC yarn, OE yarn

- Quality Control: Rigorous inspections

- Service: Monitored shipments, on-time delivery

- Exports: Western Europe, Southeast Asia, and domestic markets

Each company brings a unique set of strengths to Vietnam’s textile industry, from specialized production capabilities to international market presence and a commitment to quality and customer satisfaction.

List Of Yarn Manufacturers in Bangladesh

HA-MEEM GROUP

- Established: 1984

- Sector: Yarn manufacturing in Bangladesh

- Facilities: 26 garment factories, 300 production lines, 7 washing plants

- Output: 7 million pieces per month

- Employees: Over 50,000

- Subsidiary: Refat Garments Ltd with 26 production lines

- Exports to USA: 18,517 shipments of yarn products

KARIM JUTE SPINNERS

- Founded: 1995

- Location: Dhaka, Bangladesh

- Orientation: 100% export-oriented jute yarn and twine industry

- Capacity: 32,000 tons per annum

- Workforce: Over 4,000 workers

- Quality: Dedicated quality department with experienced staff

- Recognition: Noted as a top jute yarn exporter

- Global Exports: Worldwide distribution

JANATA JUTE MILLS LTD.

- Established: 1967

- Awards: 20 National Export Awards in 27 years

- Production: 32,000 metric tons per annum, six mills

- Main Export Markets: United States (910 shipments), Brazil (32 shipments), Pakistan, Sri Lanka, Mexico

SADAT JUTE INDUSTRIES LTD.

- Part of: Janata Group

- Founded: 1985

- Production: 2,500 metric tons

- Recognition: Multiple awards for best exporter

- Market: Suitable for small businesses, quality products at reasonable prices

ROSHAWA

- Established: 1995

- Focus: Top Bangladeshi manufacturer and exporter of 100% cotton yarn

- Reputation: Known for quality, service, and competitive pricing

- Spinning Mill: 34,000 spindles, 20,000 kg/day capacity

- Employees: Over 1,000

- Certifications: BCI, CMIA

- Technology: Modern machinery, in-house testing laboratory

Each of these companies contributes significantly to the textile industry in Bangladesh, with a strong emphasis on quality, capacity, and international export capabilities.

Do You Need Help Sourcing Yarn?

Efficiency in sourcing yarn can significantly impact the success of your textile projects. Below is a structured approach when seeking assistance:

Identifying Requirements

- Specifications: Clearly define yarn characteristics such as fiber type, weight, and color.

Supplier Engagement

- Finding Suppliers: Locate and assess potential vendors with the desired yarn.

- Negotiating: Work towards favorable terms that meet both quality and budget needs.

Sampling

- Quality Assurance: Request samples to evaluate if they align with the specified requirements.

Order Placement

- Transactions: Formalize the purchase by placing an order with the chosen supplier.

Quality Management

- Testing: Conduct thorough checks to ensure the yarn meets agreed standards.

- Quality Control: Monitor production to maintain quality consistency.

Logistics

- Shipment: Manage the logistics of getting the yarn delivered safely and punctually.

For personalized assistance, fill in the contact form to initiate the process with experienced sourcing agents.